Makino Milling Machines

Who is the world most precise machine? Lot of people might have different answers. However, Makino should be many people ideal machine for aerospace part or precise work. Today, we would like to introduce who is Makino machine tool!

In 1930, Tsunezo Makino set up his first machine shop in Tokyo, Japan. Nearly a century later, Tokyo still hosts the world headquarters of Makino Milling Machine Company. From there, Makino distributes cutting-edge machines, tools and solutions throughout Japan, Korea and Taiwan. Makino’s Tokyo Research and Development department introduced the first commercially viable horizontal machining center. They lead the industry in development and innovation of machines and systems, always driven to solve tomorrow’s problems today.

In 2006, the company developed High Energy Applied Technology (HEAT) for wire EDMs to increase speed in wire EDMing, and released the EDAC1 micro EDM ram machine. Makino is also the only manufacturer of a horizontal wire EDM, the UPJ-2. In 2007, Makino introduced SurfaceWIZARD wire EDM technology, designed to eliminate witness lines in stepped parts. Makino created ADVANTiGE™ Technology for the machining of titanium in 2010, which was recognized as a winner of Aviation Week's 2012 Innovation Challenge.

In 2018, Makino introduced ATHENA, Makino's voice-activated technology, which is designed for machine tool users. It is intended to make humans more effective at translating, assimilating and analyzing the onslaught of big data. As the industry leader in machinery design and digital innovation, Makino introduces game-changing solutions for premium performance. We produce the world’s most accurate and highest quality metal-cutting and EDM machines— horizontal machining centers, vertical machining centers, 5-axis machining centers, graphite machining centers, and wire and sinker EDMs. Over 80 years ago, our founder Tsunezo Makino invented the horizontal machining center. Today, Makinos are sold in 41 countries around the world and are widely recognized as the most advanced machining centers.

Makino machines transform your business with increased speed, reliability, precision and performance. With industry-leading precision technology and advances in software, engineering and automation, we help you reduce cycle time while maintaining unsurpassed quality. In every industry – automotive, aerospace, medical, and die/mold – Makino machines help you improve performance with every job. Take productivity to the next level. In a world dominated by deadlines, demands and down-time, we help you produce higher quality parts with less waste and repair. Horizontal, vertical, graphite machining, all types of EDM—we have a high-production, deadly-accurate machine for every setup you can dream up.

Makino reliability and easy maintenance mean your machine maintains accuracy and productivity for years, adding value and ROI far beyond any other machine on the market.

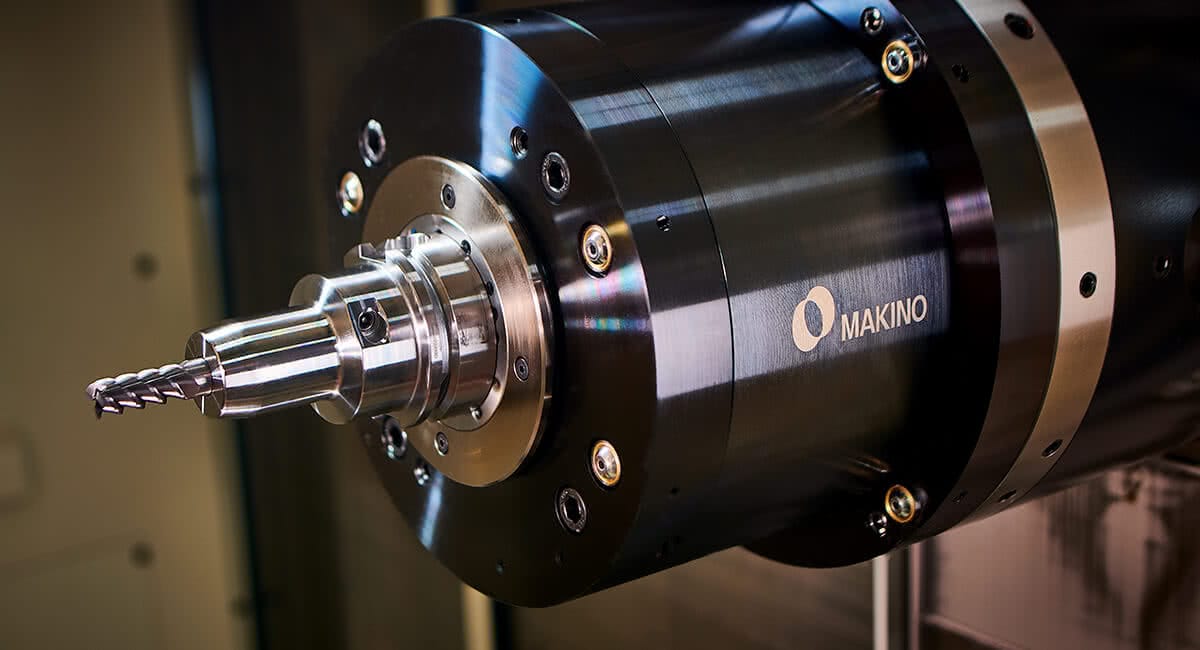

Makino leverages the latest technology in every machine. Patented technologies in our high-speed, high-performance spindles give our machines the highest repeatable metal-removal rates. That’s why Makino users lead the industry in the speed and part quality customers demand. Makino’s 1-Series machines are the top-selling 4-axis horizontals in North America, setting the industry standard. Our full line includes the MCC-Series and MCD-Series for large parts and molds made of steel and other hardened materials.

Makino 5-axis horizontal machining centers provide unprecedented levels of productivity and accuracy in the most complex, full 5-axis machining applications. Regardless of the material or process at hand, Makino’s custom technologies provide world-class efficiency in contoured parts. The ultra-high-accuracy rotary axes and superior motion-control systems eliminate compound errors and maximize accuracy while improving speed and productivity reducing part cycle times. All Makino 5-axis HMCs are configurable for automated manufacturing. When our 5-axis horizontal machining centers are integrated into an automated system, manufacturers can expect spindle utilization rates of up to 95%, and fully unattended operation over nights and weekends. By maximizing utilization, Makino 5-axis HMCs achieve the highest levels of productivity at the lowest achievable cost per part. Increase speed and precision. The Makino rotary axes’ speed reduces your cycle time, while our dynamic accuracies produce a higher quality surface finish.

Makino EDMs stand apart with the intuitive Hyper-i control system, a streamlined and efficient interface that helps you get work done faster. A large high definition 24” touch screen functions like a smart device (phone/tablet), allowing operators of all skill levels to benefit from its inviting and familiar operation that substantially reduces training requirements. The Hyper-i control further elevates an operator’s capability with several integrated advanced functions, such as hyper-linked digital manuals and video tutorials, E-Tech Doctor, and EZ-Cut that deliver higher levels of productivity to the operator’s fingertips. Makino offers a range of wire EDM machining solutions.

After knowing about Makino prodcut line and history, let's take a look on review by Makino's users: https://www.machine500.com/en/products/index/?search=makino

Reference: